Electro mechanical broaching machine Pregled

Faculty of Engineering

University of Kragujevac

Electro-mechanical broaching machine

Profesor:

Student:

Sandra Stefanović

Asad Masad

1

Abstract

Broaching is a process of metal cutting. It is about operation in one pass. The tool is broaches and

has several cutting edges. In next presentation will be explain type of tools, procedures of

treatment, methods of treatment and others. The machine used for this treatments is broaching

machine and the thesis provides a systematic model of vertical broaching machines.

Key words:

Broaching, broaching tools, broaching machine

3

1. Introduction

Broaching operation represents metal processing, where the processing is done in one pass. The

tool is broaches and designed to linearly passes perpendicular to the workpiece in the direction of

the axis of the tool. The relative movement of the tool through the workpiece provides broaching

machines (Broaching). The tool can be pushed (which is less common method of treatment), or

drawn through the workpiece. Broaching can be internal (when the tool handles the inner surface of

the workpiece) or external (when the tool processes the outer surface of the workpiece).

Technology-through processing is explained in the second chapter describes the kinematics-

through processing where we can see the position of the tool in the treatment of internal and

external broaching, broaching types, methods and types of broaching and cutting scheme.

The third chapter describes the machines for broaching of some manufacturers and their main

characteristics, the tools in the processing of broaching and their basic structural elements. Also the

choice of form space between teeth, chip breaker and handles broaches (for internal and external

broaching).

Based on the above characteristics and broaching broaches the fourth chapter was used for

modeling the electro-mechanical parts Broaching, or gear and rack, chuck tools, pole mount and an

electric motor, in the program CATIA V5R21. Before ten or more years with the Faculty of

Mechanical Engineering, professors decided to construct broaching machine, whose made almost

all the elements of the machine and it is not finished yet. Broaching is modeled according to the

already existing elements.

4

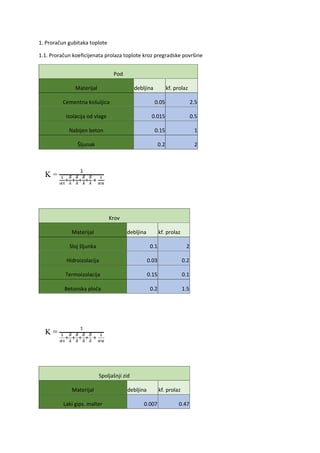

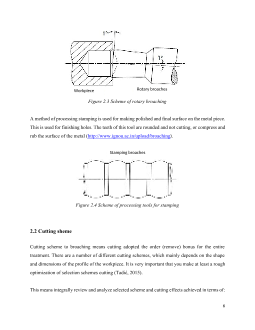

2. Proccessing of broaching

The processing of broaching characterized by high productivity in terms of high series and mass

production and high productivity of machining processes. Despite the simple kinematics

processing this treatment process is one of the most complex processes of metal processing. The

reasons are in the fact that the processing of broaching usually finishing operation and that

processing is performed at very high values of loads of tools and machines. In this connection, the

entire machining system (tools, machines, compression fittings) should be characterized by high

levels of static and dynamic stability. Due to the high cost of tools, broaching applies only in

standard, high series and mass production (Nedić, 2007).

In most cases, processing is performed by passing the linear movement tools. The workpiece do not

perform support the movement, because support movement actually does not exist, except in some

special cases (helical broaches). Support motion in some way is incorporated in the tool itself.

Processing is carried out by drawing a tool, rarely repression, along the axis of the workpiece. In

Figure 2.1 are presented processing scheme for internal and external broaching with numbered

positions. In position 1 is broaches, position 2 guides, 3. work desk, 4. the workpiece (Nedić,

2007).

Figure 2.1 Scheme of processing by broaching a) internal, b) external (Nedić, 2007)

Želiš da pročitaš svih 16 strana?

Prijavi se i preuzmi ceo dokument.

Slični dokumenti

Ovaj materijal je namenjen za učenje i pripremu, ne za predaju.