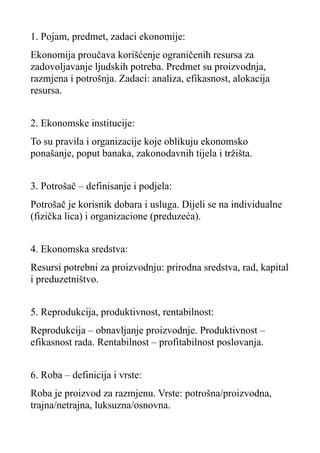

L-Nox sistem blok 3 Tent A Pregled

Nikola Tesla - Results of heat transfer

calculation

Dr. Storm / Dipl.-Ing. Erkol

Babcock Borsig Steinmüller GmbH

Belgrade, 15.08.2014

Page 2

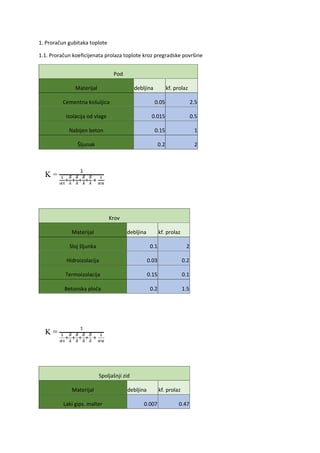

Heat calculation:

Assumptions

Babcock Borsig Steinmüller GmbH

Not depending on load:

1.

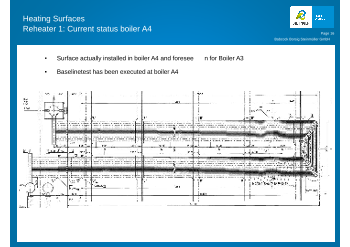

Boiler A3 and A4 are identical in construction (without regard to RH1 surface).

2.

Behavior of boiler A4 corresponds to

boiler A3 “without low-NOx modification” and “with change of RH1 surface”.

3.

Amount of cold reheat taken from cyclic process (delivered by customer) and

rechecked by heat balance of Biflux.

4.

Baselinetest coal (25.06.2014) taken from customers analysis, elementary

analysis of coal defined by statistical method acc. to FDBR.

5.

Cleanliness of heating surfaces kept constant when changing from calibration

model to low-NOx model.

6.

Change of relative burner position considered in low-NOx-model

7.

6% Burnout in OF2 (experience value taken from other boiler)

Depending on load:

1.

O

2

-Values / Excess air linearly interpolated

2.

HP-Injection: 5%, RH-Injection:0%

3.

HP outlet pressure kept constant at about ~180 bar a

Page 4

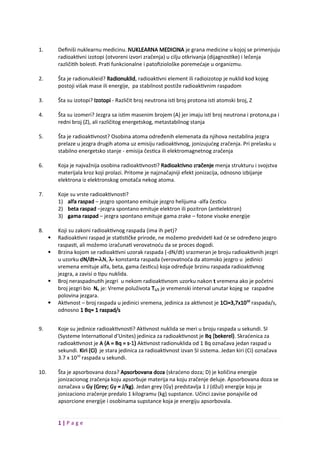

Heat calculation:

Fuel characteristics

Babcock Borsig Steinmüller GmbH

Fuel

Unit

Baselinetest:

Fuel sample

taken 25.06.

Design coal

Best coal

Worst coal

LHV

kJ/kg

8198

6700

8800

6280

Water

Ma-%

47,30

52,00

48,00

52,50

Ash

Ma-%

16,10

18,00

14,50

17,50

C

Ma-%

24,26

19,21

25,86

19,20

H

Ma-%

2,11

1,78

2,10

1,80

N

Ma-%

0,40

0,38

0,43

0,40

O

Ma-%

9,59

8,11

8,61

8,10

S

Ma-%

0,24

0,52

0,50

0,50

Page 5

Heat calculation:

Guaranteed values

Babcock Borsig Steinmüller GmbH

Fresh steam flow through the boiler

960 t/h

920 t/h

650 t/h

Pressure before the STOP valve at the HP turbine

-

177,5 bar

177,5 bar

Superheat steam temp. at the boiler outlet (SH6)

-

543 °C

543 °C

Reheat steam temp. at the boiler outlet (RH2)

-

543 °C

543 °C

Мinimum mill capacity

-

88 t/h

/

Boiler efficiency

-

≥ 88,11%

≥ 87,7%

Furnace outlet temperature (маx.)

-

1050 °C

1050 °C

NOx emission limit value (ELV)

-

*<200

mg/Nm

3

*<200

mg/Nm

3

СО NOx emission limit value (ELV)

-

*250

mg/Nm

3

*250 mg/Nm

3

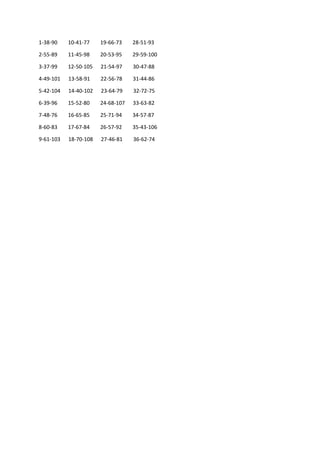

Page 7

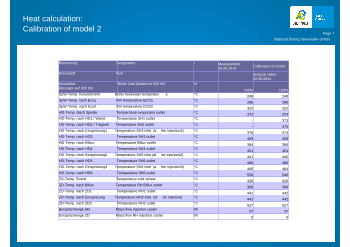

Heat calculation:

Calibration of model 2

Babcock Borsig Steinmüller GmbH

Benennung

Designation

-

Measurement:

25.06.2014

Calibration of model

Brennstoff

Fuel

-

-

Analysis taken

25.06.2014

Kessellast

(bezogen auf 920 t/h)

Boiler load (related to 920 t/h)

%

100%

100%

SpW-Temp. Kesseleintritt

Boiler feedwater temperature

°C

248

248

SpW-Temp. nach Eco1

FW temperature ECO1

°C

286

286

SpW-Temp. nach Eco2

FW temperature ECO2

°C

322

322

HD-Temp. Nach Spirale

Temperature evaporator outlet

°C

372

374

HD-Temp. nach HD1 / Wand

Temperature SH1 outlet

°C

-

373

HD-Temp. nach HD2 / Tragrohr

Temperature SH2 outlet

°C

-

375

HD-Temp. nach Einspritzung1

Temperature SH3 inlet (after injection1)

°C

376

374

HD-Temp. nach HD3

Temperature SH3 outlet

°C

409

409

HD-Temp. nach Biflux

Temperature Biflux outlet

°C

394

390

HD-Temp. nach HD4

Temperature SH4 outlet

°C

451

451

HD-Temp. nach Einspritzung2

Temperature SH5 inlet (after injection2)

°C

441

440

HD-Temp. nach HD5

Temperature SH5 outlet

°C

486

486

HD-Temp. nach Einspritzung3

Temperature SH6 inlet (after injection3)

°C

465

464

HD-Temp. nach HD6

Temperature SH6 outlet

°C

539

540

ZD-Temp. Eintritt

Temperature cold reheat

°C

326

326

ZD-Temp. nach Biflux

Temperature RH Biflux outlet

°C

368

368

ZD-Temp. nach ZD1

Temperature RH1 outlet

°C

442

442

ZD-Temp. nach Einspritzung

Temperature RH2 inlet (after injection)

°C

442

442

ZD-Temp. nach ZD2

Temperature RH2 outlet

°C

527

527

Einspritzmenge HD

Mass flow injection cooler

t/h

47

47

Einspritzmenge ZD

Mass flow RH injection cooler

t/h

0

0

Želiš da pročitaš svih 27 strana?

Prijavi se i preuzmi ceo dokument.

Slični dokumenti

Ovaj materijal je namenjen za učenje i pripremu, ne za predaju.