Model development of collaborative system for proces planning Pregled

Milosevic, M., Todic, V., Lukic, D.

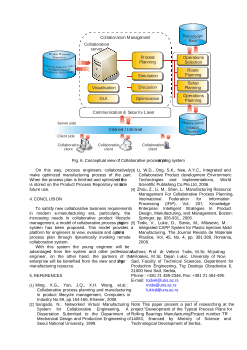

MODEL DEVELOPMENT OF COLLABORATIVE SYSTEM

FOR PROCESS PLANNING

Abstract: With competition in global markets, more and more enterprises seek to make up virtual enterprise or

cooperate with each other in the manufacturing process in order to reduce cost of product and increase competitive

ability. For this reason, some of the key technologies are developing in the field of collaborative work between

enterprise, besides collaborative design, the collaborative process planning also very important among them. With

process planning collaborative platform engineers whom belong to the different enterprise may be work more

efficiently than before, and the manufacturing resource of virtual enterprise will be utilized more optimized. In this

paper the model of system for process planning in collaborative environment are shown.

Key words: Collaborative systems, PLM, Process planning, CAPP

1. INTRODUCTION

Manufacturers are facing increasing challenges of

better

product

quality

with

tighter

delivery

requirements for customers. Global competition is

increasing with pressure on prices, smaller orders,

shorter life cycles, more suppliers and increasing

material and energy costs. These new business drivers

make

manufacturers

follow

more

competitive

manufacture

model,

such

as

collaborative

manufacturing, to closely collaborate with their

customers, suppliers, manufacturers and partners for

the most advanced competitiveness by leveraging core

competencies throughout the entire product lifecycle.

PLM systems support the management of data for

products, processes and services from initial concept,

through design, engineering, launch, production and

use to final disposal. They coordinate and collaborate

products, project and process information throughout

the entire product value chain among various levels,

internal and external to enterprise. They also support a

product-centric and process-centric solution that unifies

product lifecycle by enabling online sharing of product

and process knowledge and applications [1].

In the age of heterogeneous markets, rapid

expansion of technologies and excessive reductions in

product life cycle, collaborative engineering has been

recognized as a strategy for the total life cycle. This

collaborative engineering is getting more and more

important as manufacturing activities require more

expertise and more involvement from a lot of people on

networks, including design engineers, production

managers, process planners, production engineers,

delivery managers, customers and expert advisors.

2. COLLABORATIVE ENGINEERING

The traditional approach to product development

and production is Sequential Engineering , SE. In this

method, works are divided into many sub-tasks, and the

optimization is defined by these task sequences

(Fig. 1).

Design

Evaluation

Process

Planning

Sales,

Delivery

Production

Production

Planning

Design

Information

Part

Information

Products

Production

Plan

Process

Plan

Fig. 1. Product development and production activities

in Sequential Engineering approach

The opposite method is Concurrent Engineering,

CE. It is a systematic approach to the integrated and

concurrent design of products and their related

processes. In the concurrent engineering approach, a

complex, dependent and diverse model is used, and

optimization is determined by task dependency,

organization behavior and uncertainty.

One of the key words in current researches in

concurrent engineering is Co-operation. This co-

operation means Collaboration and it is becoming

more and more important. Consequently, Collaborative

Engineering means co-operating, sharing information

and knowledge of global and multi-company

engineering (Fig. 2) [2].

Design

Production

Process

Planning

Production

Planning

Evaluation

Sales,

Delivery

Sharing Information

and Knowledge

Fig. 2. Product development and production activities

in Collaborative Engineering approach

According to the functions and roles of users

participating in a collaborative design activity, a

collaboration product development system can be

organized in either a ‘horizontal’ or a ‘vertical’ mode.

The horizontal collaboration puts the emphasis on

gathering a design team from the same or different

disciplines to carry out a task systematically.

The vertical collaboration can establish an effective

communication channel between the upstream design

and the downstream manufacturing simulation and

optimization tools, and it can enrich the principles and

methodologies of concurrent engineering to link

diversified engineering tools dynamically. Due to these

different levels of collaboration and interaction

between users, the collaboration can be generally

categorized into three types (Fig. 3):

•

Visualization-based collaboration,

•

Co-design collaboration and

•

CE-based collaboration.

C

o

m

p

le

x

it

y

o

f

en

a

b

li

n

g

t

e

ch

n

o

lo

g

ie

s

Levels of interactions

Fig. 3. Different design processes with different

collaborations [3]

2.1 Visualisation-based collaboration

Visualisation-based collaboration has the advantage

of facilitating collaborative and distributed product or

process preview/review. In such an environment, a

multi-disciplinary team involving a manager, designer,

process planner, customer, etc., can be formed to look

at or review the same visualized design model, which is

often steered by a chief designer or chief planner. To

alleviate the sluggish transfer of large-volume design

models over the Internet, concise 3D formats for Web

applications, such as virtual reality modelling language

(VRML) or Extensible 3D standard (X3D), have been

launched to simplify the models as triangular meshes

for visualisation purposes. Under this collaboration, the

communication can be maintained through either an

asynchronous manner or a synchronous manner.

2.2 Co-design collaboration

Co-design collaboration targets a more interactive

collaboration activity for a conceptual or detailed

design with more complex requirements of co-

ordination and organization among users. Co-design

can

be

conducted

either

asynchronously

or

synchronously.

An

asynchronously

collaborative

Technologies and methodologies for collaborative

product development systems activity can be organized

in a hierarchical assembly structure, through which a

chief designer outlines the assembly configuration and

the detailed component design tasks are assigned to

individual

designers

to

carry

on

separately.

Managements, co-ordination and project review of

tasks, which can be assisted by some advanced project

management or PDM systems, are vital to the whole

process. A synchronous collaborative activity is

conducted in a way such that a group of designers are

dedicated to the same task actively. Teamwork

techniques, such as user commitment, roles and

responsibilities,

are

crucial

to

guarantee

this

simultaneous co-design activity.

2.3

CE-based collaboration

CE-based collaboration extends the CE principle,

which is based on the integration of design and the

related manufacturing processes for a life-cycle

consideration, to support distributed applications, and

geographically dispersed users, systems and resources

can be integrated in an Internet/Intranet environment

beyond the traditional boundaries of physical and time

zones. In a CE-based collaborative system, product

design systems and some evaluation or simulation

service tools diversified in terms of functionalities,

communication protocols, programming languages and

data structure representations are integrated as a multi-

disciplinary environment for optimizing design. In such

a system, application services in product design,

process planning, engineering analysis and simulation,

can be conveniently embedded as Application Service

Providers

(ASPs)

for

remote

invoking

and

manipulation.

2.4 Product lifecycle collaboration

As such, a new technology solution, called,

‘‘product

lifecycle

collaboration’’,

is

required.

Functions of to enable product lifecycle collaboration

include, but not limited to (Fig. 4) [1]:

•

Product portfolio management,

•

Collaborative product customization,

•

Collaborative product development,

•

Collaborative product manufacturing,

•

Collaborative component supply and

•

Extended product service.

Želiš da pročitaš svih 4 strana?

Prijavi se i preuzmi ceo dokument.

Slični dokumenti

Ovaj materijal je namenjen za učenje i pripremu, ne za predaju.